HRC 400 Series Rebar couplers // types and dimensions

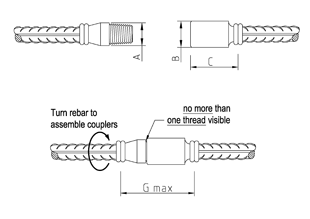

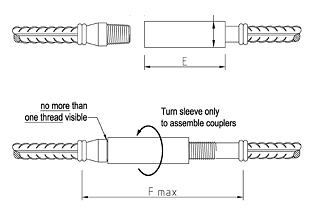

Standard coupler | Position coupler |

HRC 410C/420 | HRC 410/490 |

|  |

| Bar designation | Sleeve and Thread Dimensions | |||||||

|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F max | G max | Torque* | |

| mm | mm | mm | mm | mm | mm | mm | Nm | |

| 15M | 28 | 28 | 50 | - | - | - | 76 | 135 |

| 20M | 35 | 35 | 55 | - | - | - | 90 | 135 |

| 25M | 38 | 42 | 76 | - | - | - | 115 | 135 |

| 30M | 42 | 42 | 90 | 55 | 157 | 330 | 135 | 200 |

| 35M | 48 | 48 | 90 | 57 | 160 | 330 | 150 | 200 |

| * Recommended torque for fatigue or earthquake loads. | ||||||||

- Coarse tapered threads for robustness + fast and easy installation.

- Easy and reliable visual quality control – no tool required.

- Designed to transfer at least 700MP tensile stress. Thus the real stress and strain capacity of almost every spliced rebar can be used (no loss of ductility!)

- Fulfils and exceeds all requirements of ISO 15835 “Reinforcement couplers for mechanical splices of bars” (including fatigue and earthquake classes)

- Independently tested to comply with the requirements of:

- EN ISO 19903 “Petroleum and natural gas industries – Fixed concrete offshore structures”

- CSA N287.2-08 “Material requirements for concrete containment structures for CANDU nuclear power plants” (for tensile, compression and cyclic loads)

- Successful tested at low temperature (-20⁰C)

- Can be combined with other HRC products, as HRC 100 Series

- Standard product length 200-15,000mm